Laser Cutting is one of the most popular metalworking processes due as it can cut sheet metal with precision, allowing parts of varying sizes and thicknesses to be obtained. Cutting is carried out using a guided laser beam that penetrates the material until it melts and cuts it. This very versatile industrial process can be used safely and with high quality on various types of metal, including steel and aluminium.

The main advantages of laser cutting on metals are as follows:

- Flexibility

- Precision

- Repeatability

- Speed

- Automation

Let’s explore them one by one.

Flexibility

Laser cutting does not require any change of tools when sheet metal is being cut. The same configuration can be used to cut many different shapes of the same thickness. In addition, it allows different shapes to be formed from a single sheet of metal by means of accurate nesting.

Precision

Precision is one of the main advantages of laser cutting compared to other cutting methods. A laser beam heats the material only at the point where it is cut, without the rest of the material undergoing any thermal alteration. Laser cutting therefore provides an opportunity to obtain smooth, burr-free profiles, minimising the need for additional finishing treatments.

Repeatability

Accurate design of the cutting line allows the production of large-scale objects, as well as small batches with many variants, always with the guarantee of obtaining parts that are exact replicas of each other.

Speed

Laser cutting is faster than traditional mechanical cutting methods, especially when complex and varied processes are involved. The more powerful the laser cutting, the faster the parts are produced.

Automation

Laser cutting is not very labour-intensive, since modern systems are highly automated and have a large production capacity. The expertise of the skilled laser cutter still plays an important role in the quality of the finished product, however, the cutting speed and low manual labour requirements lead to lower costs compared to other cutting methods.

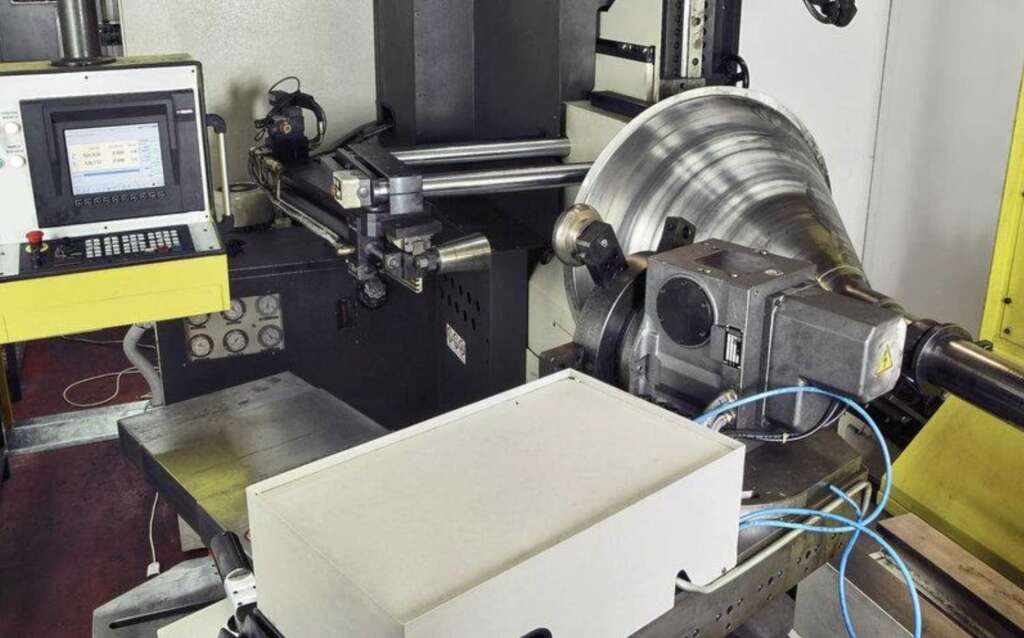

In order to guarantee its customers an excellent service and fast, flexible delivery times, the Pesce Metal Factory fleet of machines includes:

- A TruMatic 1000 fiber, 3000 W, laser/punch combination machine for cutting iron, steel, aluminium, copper and brass up to 5 mm thick.

- A TruLaser 3030 CO2, 3200 W, laser machine for cutting iron up to 20 mm thick, steel up to 10 mm thick, aluminium up to 6 mm thick, with an automated Fasani Automazioni sheet metal loading and unloading system.

- A Domino Prima Industrie CO2 2D/3D, 3500 W, laser