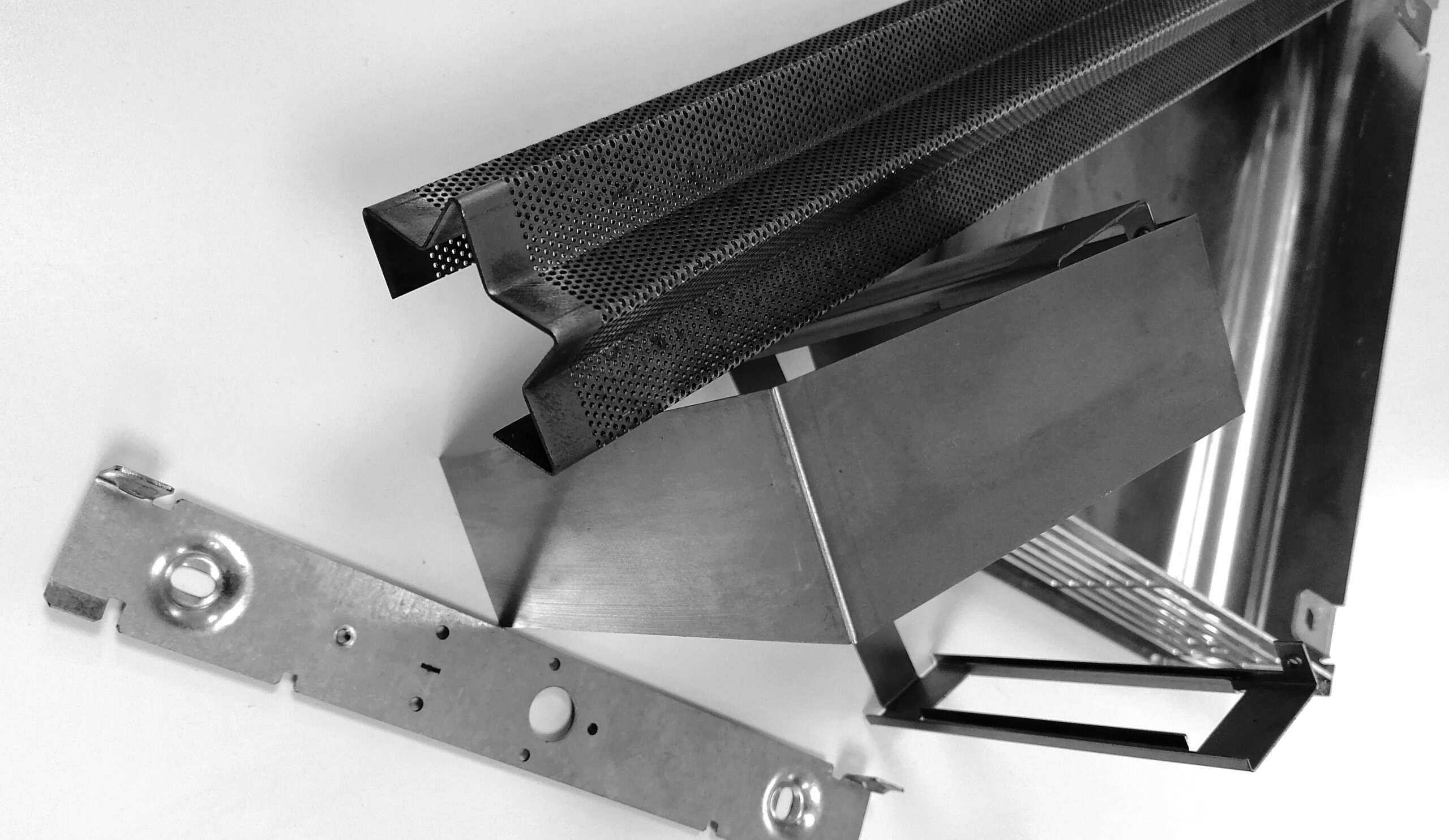

To improve performance and offer customers an increasingly comprehensive service, Pesce Metal Factory has chosen to rely on TRUMPF as a partner for its bending department.

Thanks to the new TRUMPF TRUBEND 7050 press brake, PMF is further increasing the quality of its workmanship, producing high quality products, made with safe and cutting-edge machinery.

Technical Advantages of the New TRUMPF 7050

Technical Advantages of the New TRUMPF 7050

This new machine, despite its exceptional compactness, represents the top of the range in terms of technology and output quality, especially for the bending of small to medium-sized parts.

Thanks to offline programming (performed through the Teczone bend software), direct drive of the axes, and the angle measurement system, Pesce Metal Factory is now able to produce extremely precise products, maintaining high levels of productivity.

A choice that goes beyond the productivity increase

In addition to the quality and productivity aspects, PMF chose this new bending machine because it complies with its occupational health and safety policy.

In addition to the quality and productivity aspects, PMF chose this new bending machine because it complies with its occupational health and safety policy.

Indeed, PMF firmly believes that in order to work efficiently, the operator must be able to act in complete safety.

Hence the choice of the TRUBEND 7050 bending machine: the first bending machine with certification of compliance with ergonomics regulations, where the worker can configure his workstation to suit his needs so as not to strain his spine.

Finally, the machine is also equipped with an integrated LED lighting system, which contributes to improved visibility in the working area, for greater comfort and ease of movement.