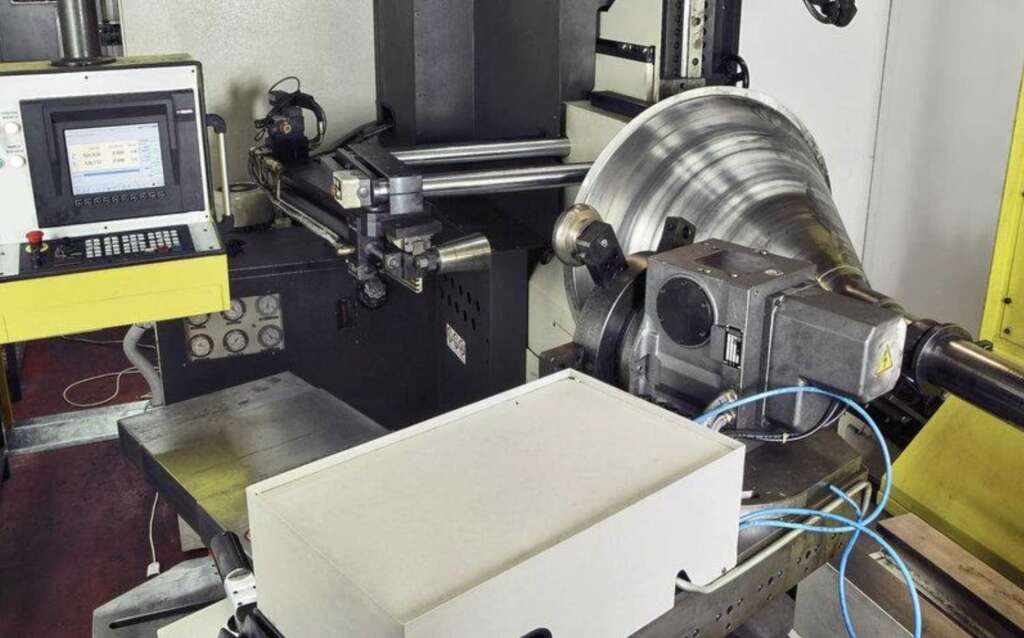

The die design stage for sheet metal turning is the fundamental step in starting sheet metal turning processes that can meet specific design requirements, thereby also optimising time to market.

Dies for designer Chandeliers

To make custom dies for lamps, it is essential for the technical team to have an IT infrastructure that can interface and dialogue with cutting-edge design tools, so that every detail of the custom die-making process can be checked and monitored.

More specifically, it is also crucial to know the intended use of the die, since the subsequent turning process must also be based on the materials selected. These need to be appropriate for any machining and finishing needed such as punching, which is more suited to softer metals such as copper and aluminium, or for special lighting solutions, for example outdoor lighting that requires a more weather-resistant material such as stainless steel.

The synergy between the die design stage and the manufacturing stage is always highly important, as it allows all the project steps to be optimised, especially when the subsequent production process (cutting, cold turning, coating) is carried out in-house, as in the case of Pesce Metal Factory.

Pesce Metal Factory supplies various industrial sectors

Lighting and design companies send us their projects for modern and functional pendant, floor and table lamps, tops and columns for tables, as well as chairs made of iron, aluminium, copper and brass. Thanks to our technical consulting service, the dies for these projects are created to manufacture components, using sheet metal turning and cold stamping. We work with national and international companies not only in the design sector but also in the fields of thermo-ventilation, industry, food and agriculture, operating as a sound and reliable partner for light carpentry and metal cold forming.

For further information, please fill in the form.