In the article, we will discover the production process of bending metal, a metal carpentry process that is much appreciated in the industrial field. It allows sheet metal to be bent and deformed to obtain specific shapes or some structures to be stiffened thanks to the bending action of the die on the piece.

The processing is made possible by the property of metals known as “neutral fibre“, which deforms without elongating or contracting. To achieve an excellent result, it is necessary to choose a metal that is sufficiently plastic, i.e. with the ability to withstand large deformations before reaching breaking point.

Types of metal and metal bending applications

The most frequently bent metals are iron, aluminium and alloys such as steel, bronze and brass.

The bending process is very versatile and allows high-quality flat semi-finished sheet metal to be obtained, which can be used in many different fields, including in the carpentry, construction, railway and automotive industries.

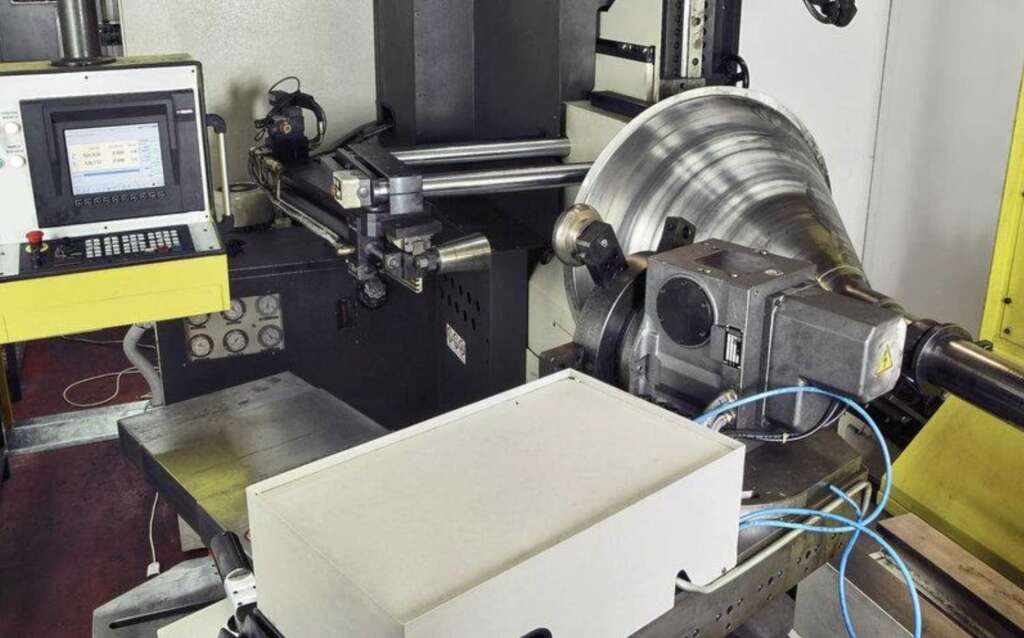

Pesce Metal Factory carries out sheet metal bending processes with the aid of cutting-edge machinery, which guarantee, thanks to our expert technicians, products of excellent quality in both aesthetic and functional terms

Pesce Metal Factory offers its customers the opportunity to perform this processing on metals up to 3000 mm in dimension with a thickness of 2 mm.

Contact us for further information about this process.