Project Description

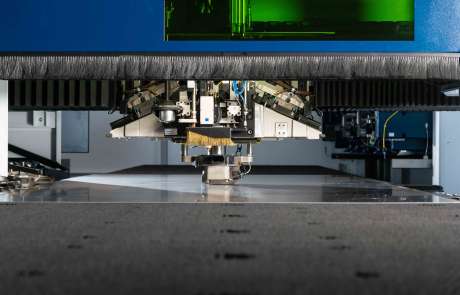

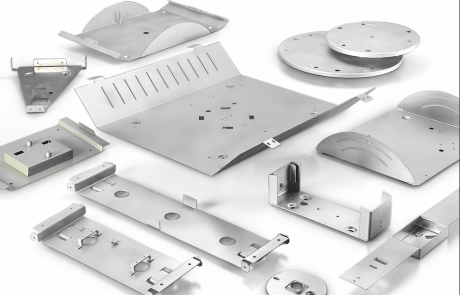

CNC punching and 2D/3D LASER CUTTING

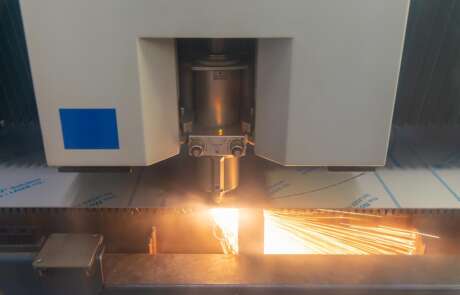

2D/3D laser cutting is one of the processes that Pesce Metal Factory makes available to its customers.

The laser cutting process uses a beam of light emitted by a special lens that heats sheet metal until it melts and cuts it. The laser beam then follows the set cutting path.

DETAILS OF THE CNC PROCESSING AND 2D/3D LASER CUTTING