Project Description

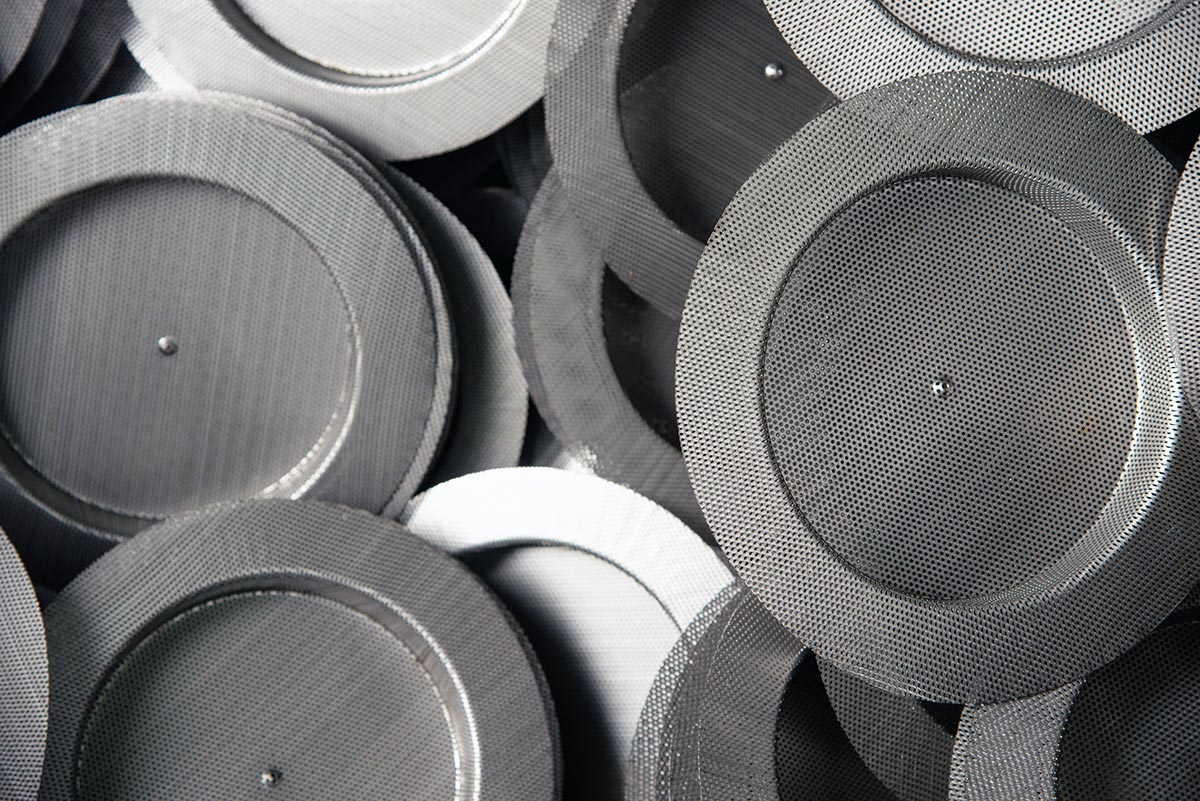

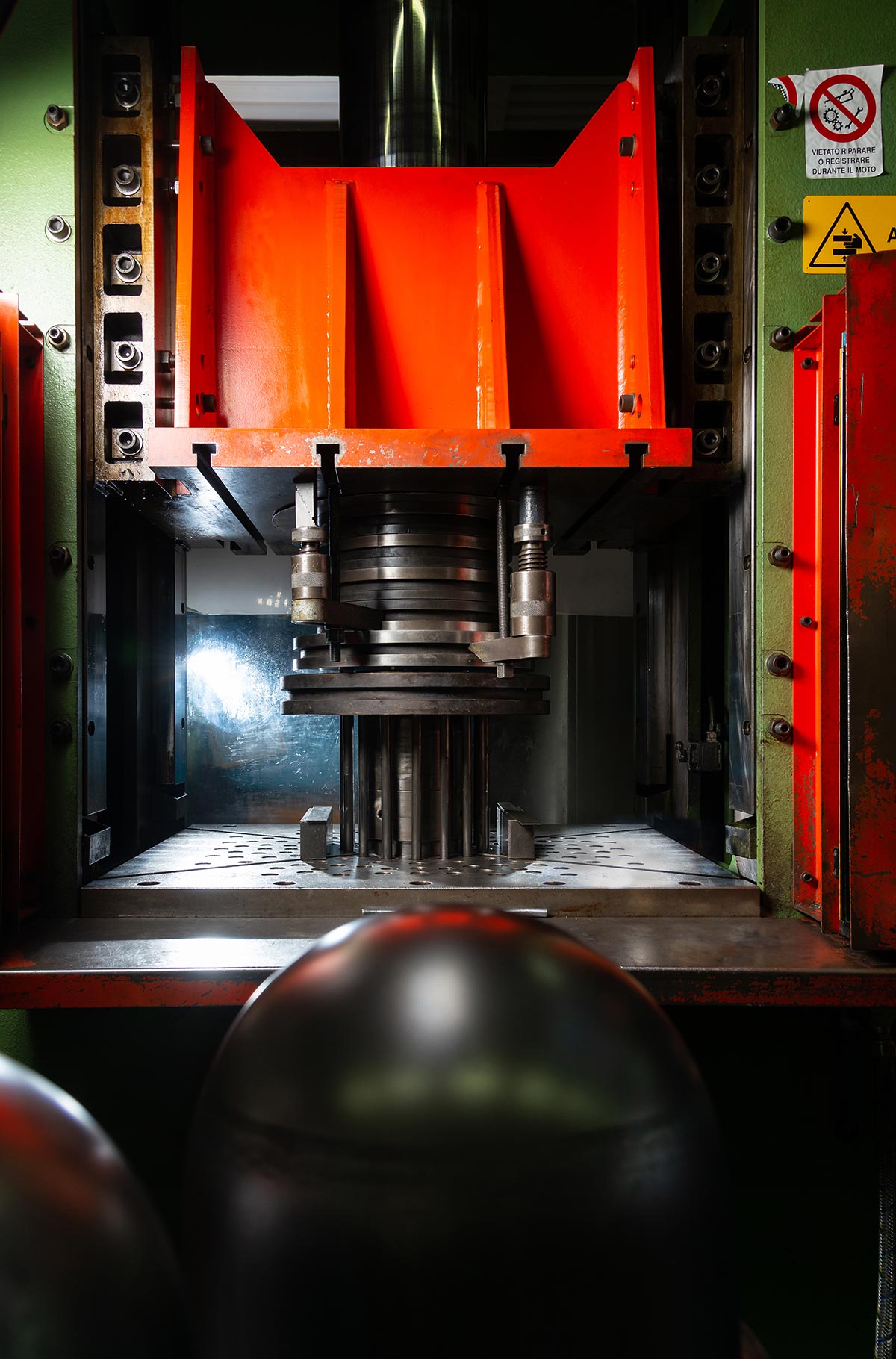

METAL CARPENTRY

Pesce Metal Factory specialises in metal carpentry, in particular in metalworking processes such as metal turning, metal cutting and metal spinning. Our products are employed in different industries, from Agricultural Machinery, to Furniture Design.

METALCARPENTRY AND METALWORKING PROCESS